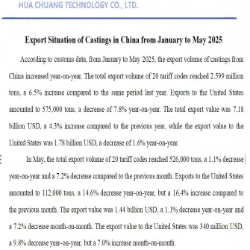

According to customs data, from January to May 2025, the export volume of castings from China increased year-on-year. The total export volume of 20 tariff codes reached 2.599 million tons, a 6.5% increase compared to the same period last year. Exports to the United States amounted to 575,000 tons, a decrease of 7.8% year-on-year. The total export value was 7.18 billion USD, a 4.3% increase compared to the previous year, while the export value to the United States was 1.78 billion USD, a decrease of 1.6% year-on-year.

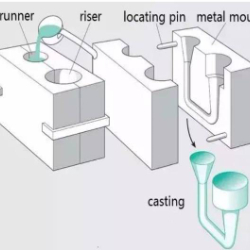

The production method where molten metal is poured into a mold cavity matching the shape and dimensions of the part, allowed to cool and solidify to obtain a blank or part, is commonly referred to as Metal Liquid Forming or Casting.

Casting serves as an indispensable component for the development of the equipment manufacturing industry and is widely used in high-end manufacturing sectors such as automotive, machine tools, instruments and meters, construction machinery, shipbuilding, and aerospace.

Lost foam casting (LFC) is a trans formative casting process that offers significant advantages in terms of design flexibility, cost efficiency, and high precision. By using a foam pattern that evaporates when molten metal is poured, this method allows for the creation of complex, intricate parts. Below is an exploration of various products from different industries that are well-suited for production using lost foam casting:

On September 19, 2024, the 6th Asian Casting Forum was held at the Bangkok International Trade & Exhibition Centre in Thailand. During the forum, the Japan Foundrymen's Society, the Indian Foundrymen's Association, the Taiwan Foundry Industry Association, the Indonesian Foundry Association, and the China Foundry Association shared insights into the changes that have taken place in the casting industry in recent years, each from different perspectives. We have summarized the content of the reports and, through a Q&A format, attempted to observe the development of the Asian casting industry from different dimensions.

3D printing is the process of creating objects by adding material layer by layer, enabling the production of complex geometries and highly precise details. Compared to traditional subtractive manufacturing methods, 3D printing reduces material waste and production time, offering significant flexibility.

Export Situation of Chinese Castings from January to July 2024

Basic Characteristics of Industry Operation in the First Half of 2024,Highlights in industry development

2024 Foundry Expo, Die Casting and Nonferrous Metals Exhibition

The thin-walled parts produced by LFC process are easy to deform. By adjusting the mold splitting process, bead density, mold assembly process, coating, drying support, vibration and other process schemes.

Through product structure optimization, overall foam consideration, reasonable buried box vibration process Process strengthening rib and other measures to reduce deformation and waste products.

Lost foam casting technology as a casting near static forming method has been developed rapidly in recent years. In foreign countries, the lost foam casting technology has shown strong vitality due to the mechanized and automated lost foam casting production lines and the significant economic and social benefits.